P295 – 4″ UHV sputter deposition cluster tool IPHT

Application

UHV sputter deposition cluster tool for thin film and multilayer deposition at 4″ substrates

Year of delivery

2011

Installation site

IPHT, Jena, Germany

Design Features

- HV magnetron sputter deposition cluster tool with confocal sputtering configuration.

- In three sputter chambers up to four 3″ magnetrons with manual in situ tilting can be installed.

- Fully motorized 2 axes sample manipulators with integrated sample clamping stage, pneumatic sample shutter, RF back sputtering option installed and sample temperature stabilization (mild cooling and mild heating).

- Oxydation chamber with dynamic as well as static oxydation pressure regulation.

- Load lock chamber with motorized storage for three samples.

- Automatic sample transfer between all chambers via a radial distribution chamber.

Special Features

- At least two different sample sizes (4″ and 6″ wafer) can be handled (using different kind of sample adapters).

- Ar gas backside cooling installed at all sputter chamber sample stages.

Outer Dimensions

Technical specifications and performance values

General

Sputtering chamber (SP1, SP2, SP3)

Size

About 600 mm diameter, about 720 mm height

Material

stainless steel

Load lock chamber

Size

About 250 mm diameter, about 310 mm height

Material

stainless steel

Oxidation chamber

Size

About 300 mm diameter, about 500 mm height

Material

stainless steel

Radial distribution chamber

Size

About 1000 mm diameter, about 450 mm height

Material

stainless steel

Vacuum

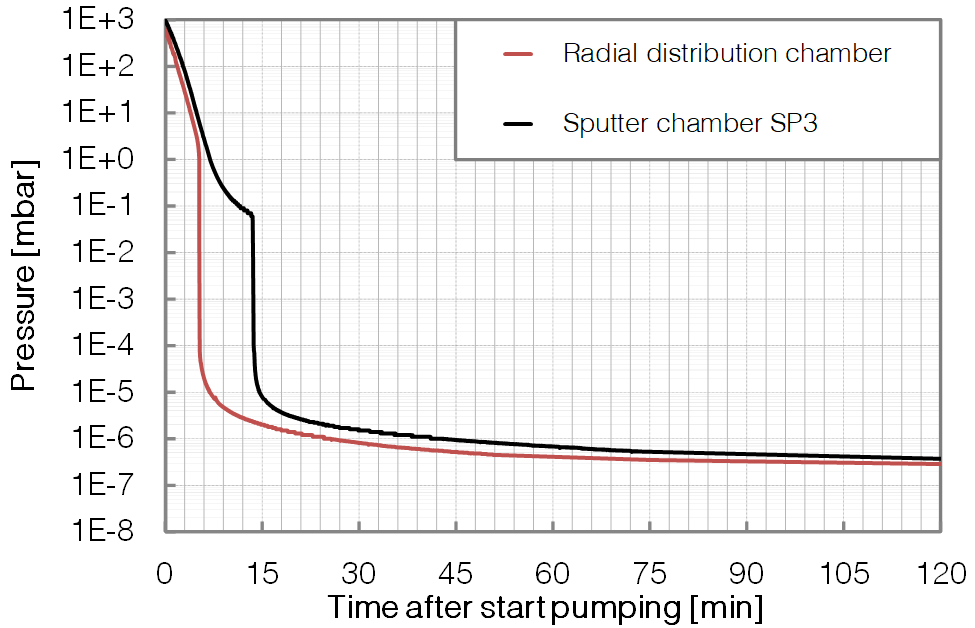

Sputtering chamber (SP1, SP2, SP3)

Base pressure

< 2 * 10-8 mbar

Pump down time

1 hour to < 4 * 10-7 mbar

Chamber pumping

Cryo pumping stage, chamber lid differentially pumped by dry foreline pump

Load lock chamber

Base pressure

< 3 * 10-8 mbar

Pump down time

1 hour to < 2 * 10-7 mbar

Chamber pumping

Turbo pumping stage with dry foreline pump

Oxydation chamber

Base pressure

< 3 * 10-7 mbar

Pump down time

1 hour to < 10-6 mbar

Chamber pumping

Turbo pumping stage with dry foreline pump

Radial distribution chamber

Base pressure

< 5 * 10-8 mbar

Pump down time

1 hour to < 4 * 10-7 mbar

Chamber pumping

Turbo pumping stage with dry foreline pump

Manipulator features

Sputtering chamber (SP1, SP2, SP3)

Sample size

nominal diameter 4″ substrate

(diameter max. 6″ substrate)

Motion axes

Motorized sample roation axis

Sample clamping tool with motorrized sample release unit (part of the manipulator head) for optimized thermal contact

Pneumatic sample shutter (part of the manipulator head)

Temperatures

0°C up to +100°C at sample

Special features

Sample bias and sputter cleaning (RF, DC or pulsed DC) is possible

Load lock chamber

(Sample storage)

Storage size

3 sample holders

Sample size

diameter max. 4″ substrate

Motion axes

motorized z translation of the sample storage stage

Sample preparation features

Oxydation chamber

Dynamic oxydation pressure (regulation)

0.01 mbar up to 1 mbar

upstream as well as downstream pressure regulation implemented

Static oxydation pressure

> 1 mbar up to 50 mbar

Special features

Gas inlet via manual dosing valve in combination with mass flow controller

Pneumatic blocking valves at both gas inlet lines installed