P321 – HV inline sputter deposition system INCOATEC

Application

HV inline sputter deposition system for thin film and multilayer deposition at special sized substrates for X-Ray mirror production

Year of delivery

2012

Installation site

INCOATEC GmbH, Geesthacht, Germany

Design Features

- Inline HV magnetron sputter deposition system with full automatic control system for x-ray mirror production with very high film uniformity below 1%.

- Four rectangular magnetrons (target size: 12″ x 3.5″) in face to face configuration.

- Each magnetron mounted at a differentially pumped fliping door for fast and easy target exchange and source cleaning.

- Source shutter and direct gas inlet close to the target installed at each magnetron.

- Low pressure sputtering possible.

- In situ adjustable (stepper motor driven) aperture between targets and substrate.

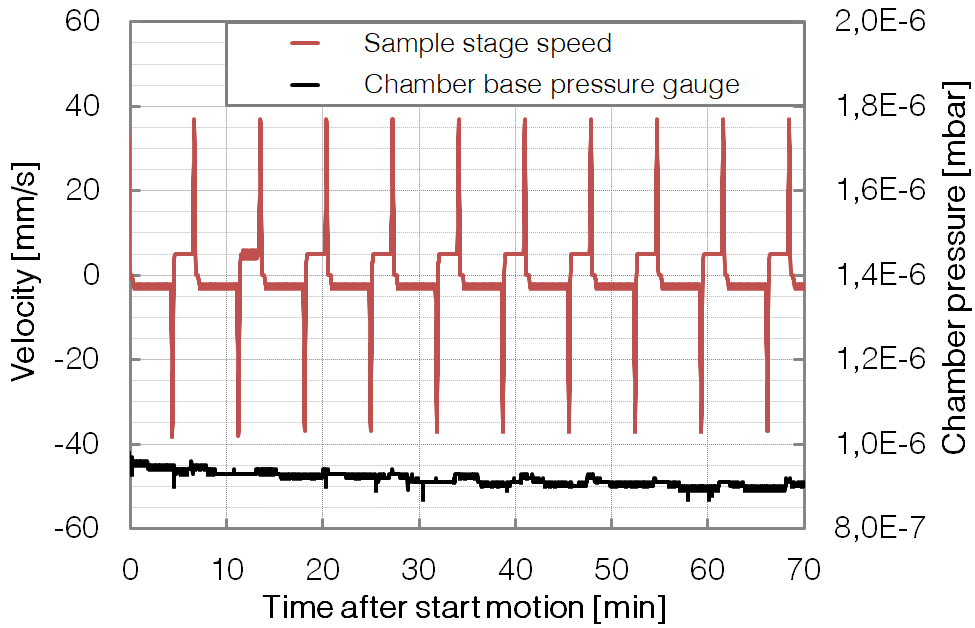

- Motorized sample trolley with speed profile motion mode as well as constant speed motion mode implemented.

- Encapsulated and differentially pumped ball screw spindle drive.

- Maximal sample size of 400mm x 160mm x 80 mm.

- Residual gas analysis installed at the sputtering chamber.

- Load lock chamber with automatic sample transfer system and sliding access door.

Special Features

- Large motion speed range from about 33 µm/s up to 50mm/s possible.

- Optical system for backlash detection of the motion drive spindle.

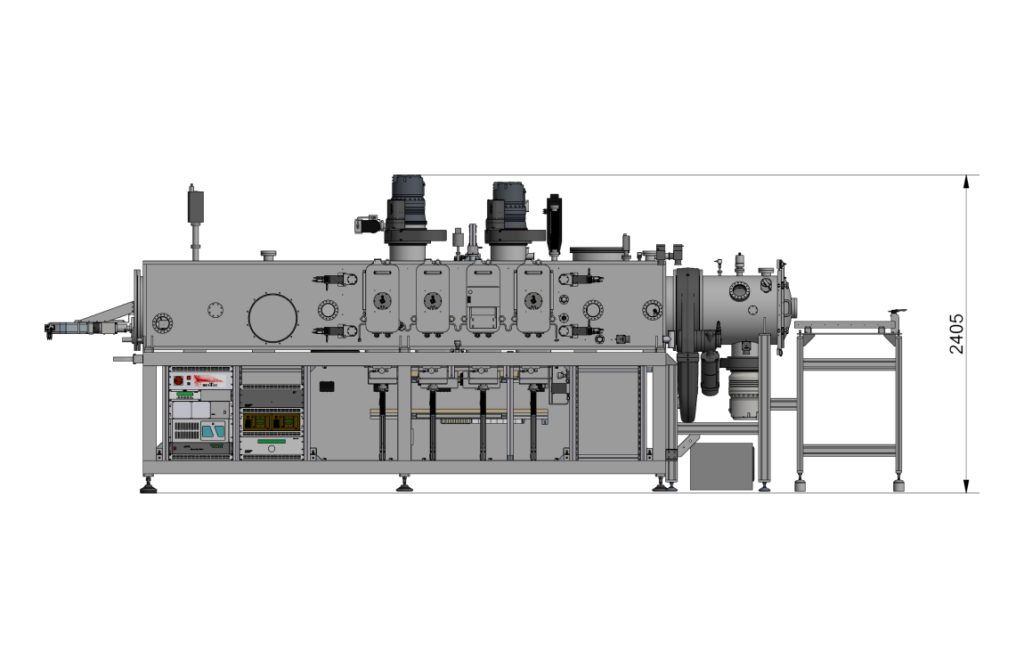

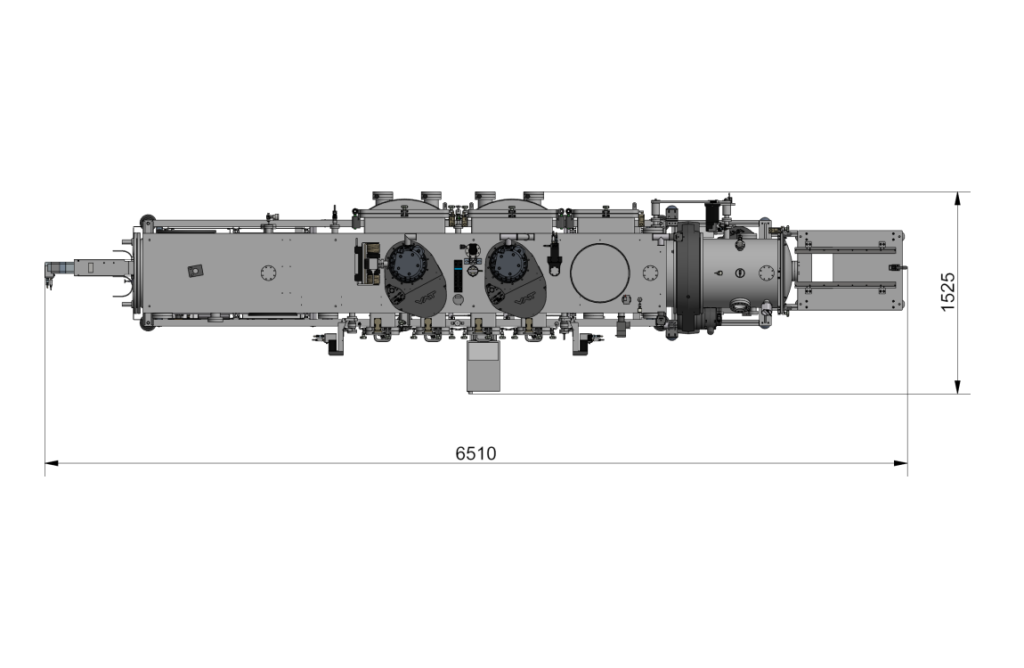

Outer Dimensions

Technical specifications and performance values

General

Sputtering chamber

Size

Cubic shape chamber, about 4060 mm length, about 880 mm width & about 800 mm height

Material

stainless steel

Load lock chamber

Size

500 mm diameter, about 615 mm length

Material

stainless steel

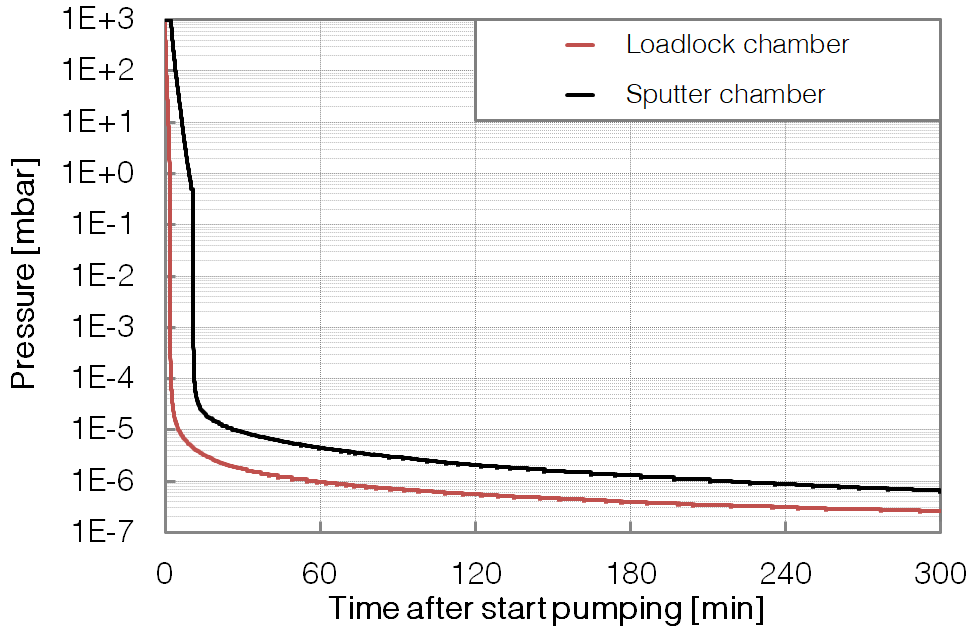

Vacuum

Sputtering chamber

Base pressure

< 10-7 mbar

Pump down time

8 hours to < 10-8 mbar

Chamber pumping

Turbo pumping stage incl. water vapor cryo trap, several chamber doors are differentially pumped by dry foreline pump

Load lock chamber

Base pressure

< 2 * 10-6 mbar

Pump down time

1 hour to < 10-5 mbar

Chamber pumping

Turbo pumping stage with dry foreline pump

Manipulator features

Sputtering chamber

Sample size

max. 400mm x 160mm x 80 mm special shaped samples

Motion axes

Motorized sample translation axis with motion speed range of min. 33 µm/s up to max. 50 mm/s, incl. speed profile feature