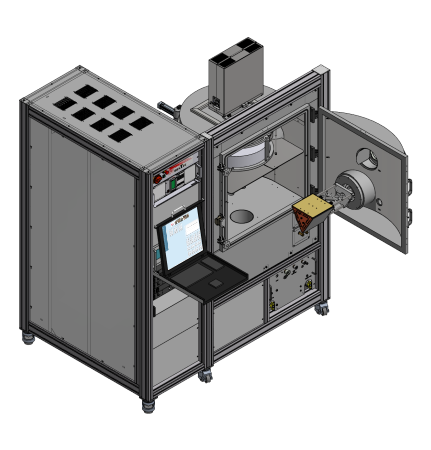

P365 – 17″ HV Ion beam sputter deposition system TopTec

Application

HV ion beam sputter deposition system for thin film and multilayer deposition at 17″ substrates

Year of delivery

2013

Installation site

TopTec, Turnov, Czech Republic

Design Features

- HV Ion Beam sputter deposition system in combination with ion beam assisted deposition.

- 75mm DC ion source oriented towards a target manipulator with three 200 mm x 200 mm targets.

- Sample manipulator with motorized sample rotation, pneumatic shutter and maximal sample temperature of 300°C.

- Second ion source for sample precleaning, mild etching, plasma treatment and ion beam assisted deposition (IBAD).

Special Features

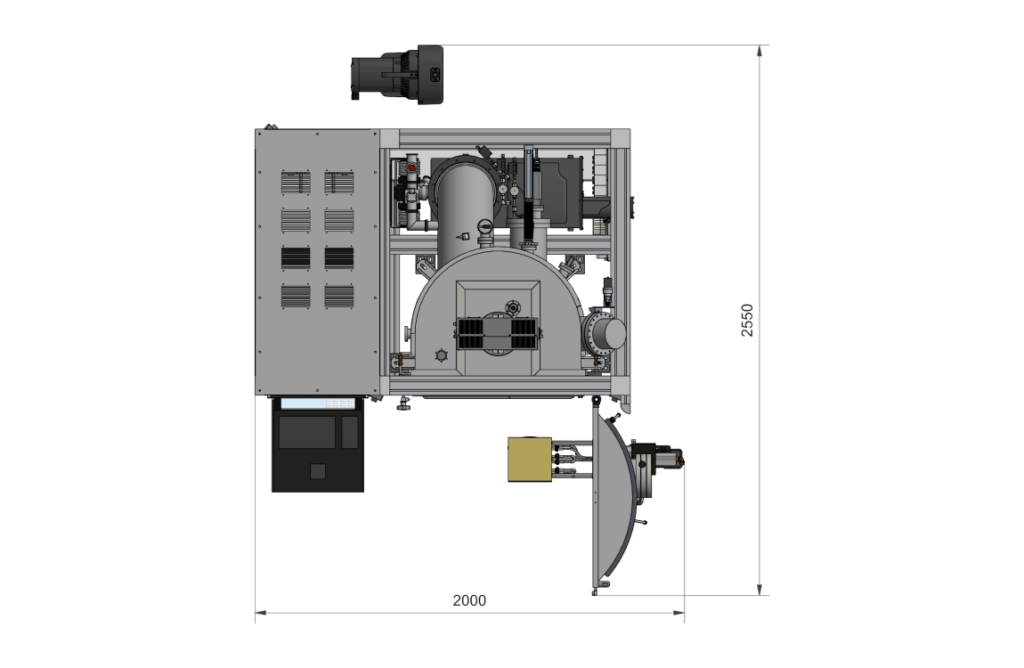

- System integration in clean room wall (door and user interface is in clean room; rest of the sytem is in gray room).

- Sample manipulator can be equipped with at least two different stage heads.

- Stage head 1 for one samples with diameter of max. 450mm (max. 25kg).

- Stage head 2 for three samples with diameter of max. 200mm diameter.

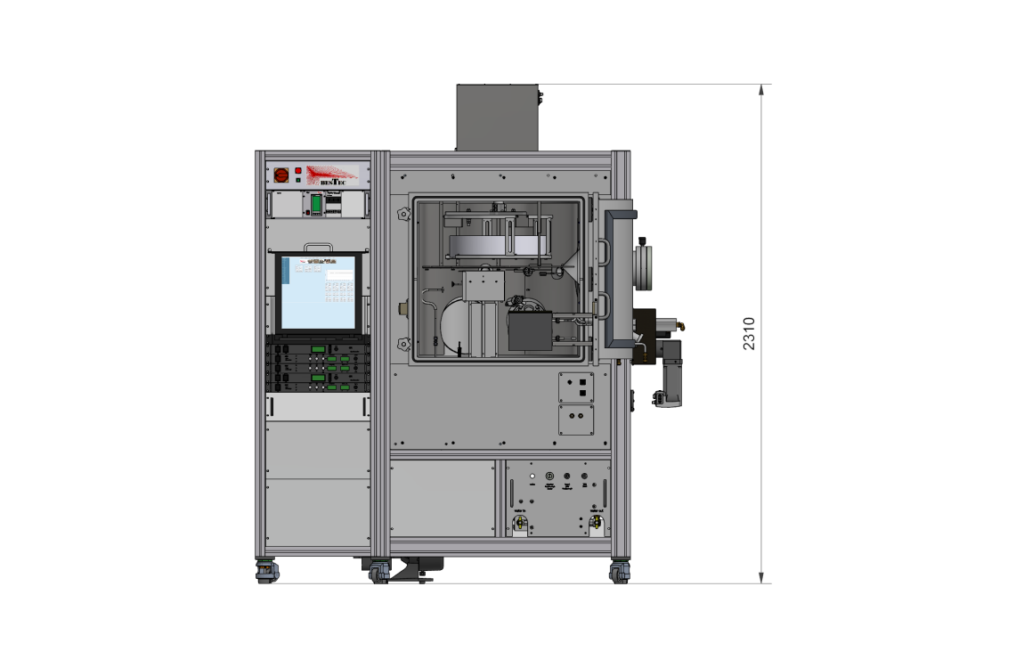

Outer Dimensions

Technical specifications and performance values

General

Sputtering chamber

Size

About 750 mm width, about 870 mm depth, about 720 mm height (D-shape chamber with door)

Material

stainless steel

Vacuum

Sputtering chamber

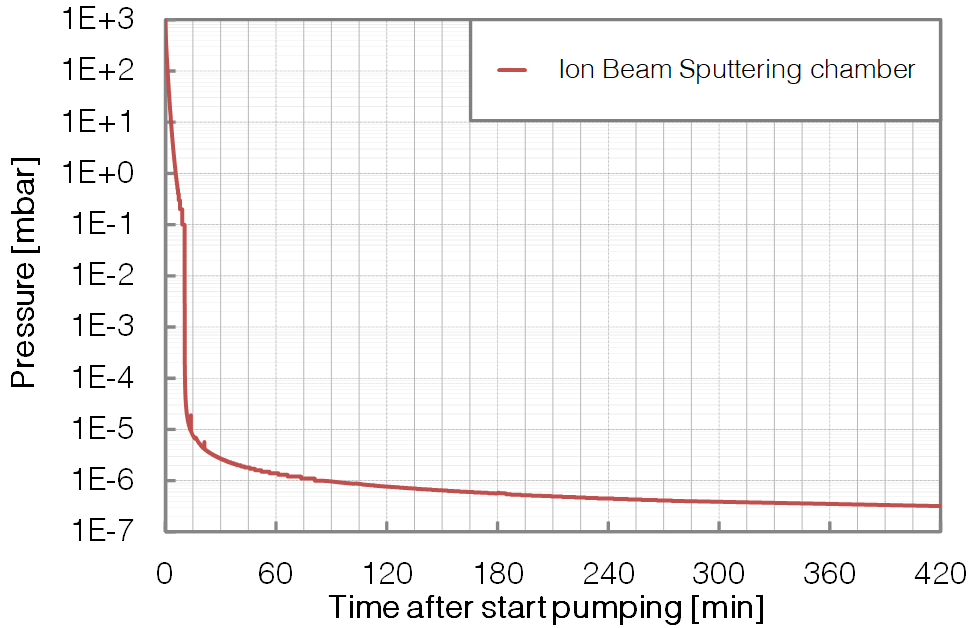

Base pressure

< 10-7 mbar

Pump down time

3.5 hours to < 5 *10-7 mbar

Chamber pumping

Turbo pumping stage with dry foreline pump

Manipulator features

Sputtering chamber

Sample size

Sample stage head 1: diameter max. 450 mm substrate (max. 25kg)

Sample stage head 2: three samples with diameter max. 200 mm substrate

Motion axes

max. 2 motorized axes (depending on mounted sample stage head)

Sample stage head 1: motorized (continous) sample stage rotation

Sample stage head 2: motorized (continous) sample stage rotation incl. planetary rotation at each sample

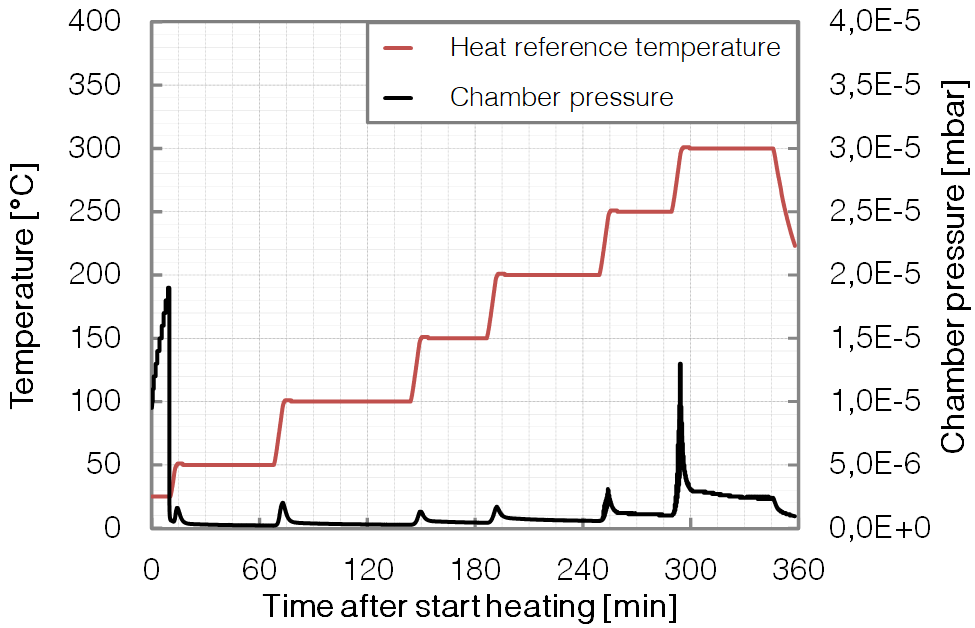

Temperatures

Room temperature (not stabilized) up to 300°C at sample

Sample preparation features

Sputtering chamber

Plasma treatment

Up to 5E-4 mbar partly ionised argon gas (using a griddless ion gun)

Ion beam etching /

sample precleaning

Wide range variation of ion energy and ion beam current