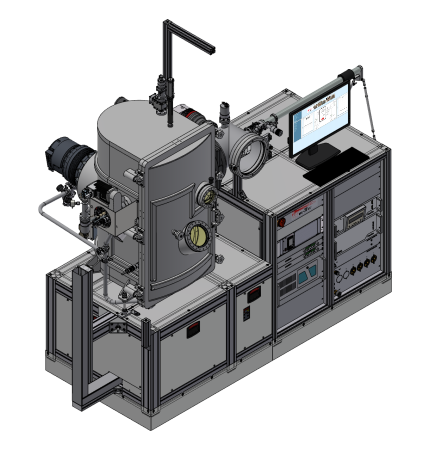

P397 – 7″x7″ HV e-beam deposition system CEITEC

Application

HV e-beam deposition system for thin film and glacing angle deposition at maximal 7″x7″ substrate.

Year of delivery

2015

Installation site

CEITEC, Brno, Czech republic

Design Features

- HV e-beam deposition system for thin film deposition.

- Moveable multi pocket e-beam source.

- Motorized pocket exchange and z motion for automatic deposition processes.

- Thickness controller incl. rate regulation and end point detection.

- Thickness sensor with shutter for extended crystal life time when rate regulation is not active.

- Fully motorized 2 axes sample manipulator with integrated pneumatic sample shutter and maximal sample temperature well above 800°C.

- Integrated bake out system.

- Load lock chamber including sample preparation stage.

- Dosing gas inlet valve for oxydation or nitration.

- Optional:

- Ion source for sample precleaning and mild etching.

- Two effusion cells.

- Thermal evaporation source.

Special Features

- Very large distance variation between sample and e-beam source possible (mechanically limited to 190mm travel).

- Different sample sizes from 7″ x 7″ sample plates down to 10mm x 10mm wafer pieces can be handled (using different kind of sample adapters).

Outer Dimensions

Technical specifications and performance values

General

E-Beam chamber

Size

About 540 mm width, about 590 mm depth, about 1050 mm height (D-shape chamber with door)

Material

stainless steel

Load lock chamber

Size

250 mm diameter, about 250 mm height

Material

stainless steel

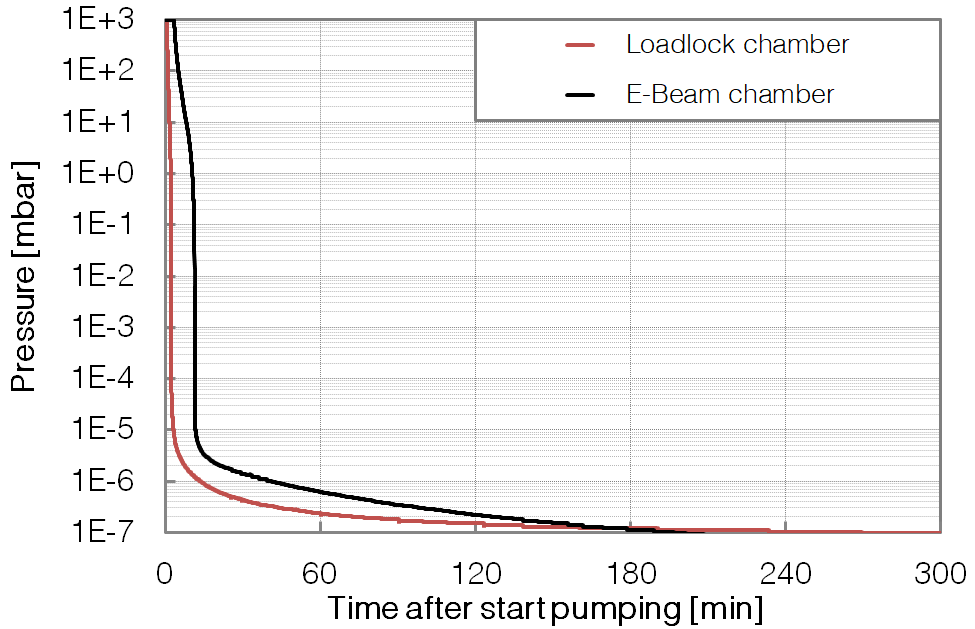

Vacuum

E-Beam chamber

Base pressure

< 5 * 10-8 mbar

Pump down time

3.25 hours to < 10-7 mbar

Chamber pumping

Turbo pumping stage, chamber door differentially pumped by dry foreline pump

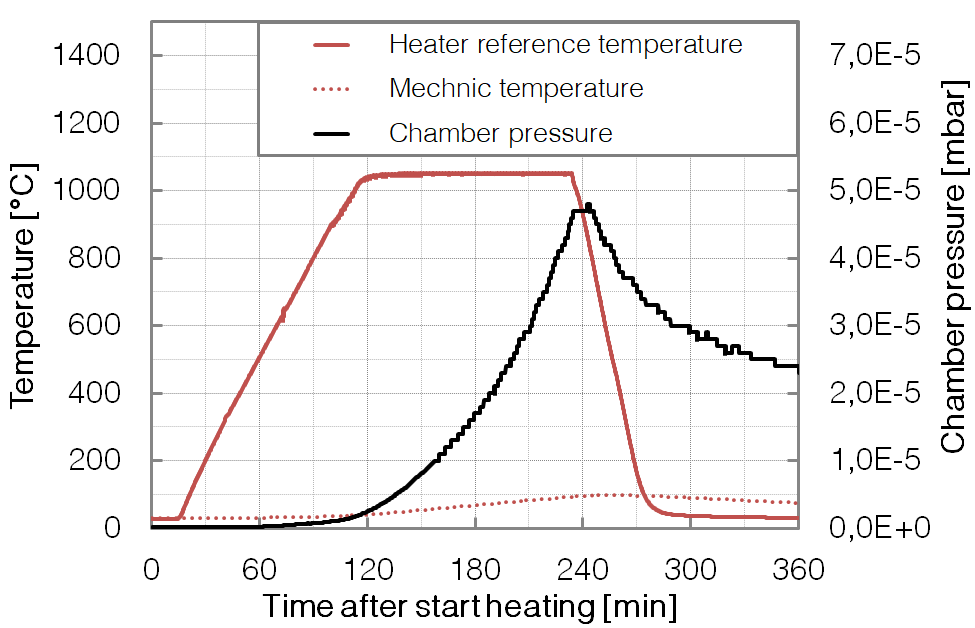

Bake out

< 120°C

Load lock chamber

Base pressure

< 10-7 mbar

Pump down time

0.5 hours to < 5 * 10-7 mbar

Chamber pumping

Turbo pumping stage with dry foreline pump

Manipulator features

E-Beam chamber

Sample size

max. 7″x7″ substrate

Motion axes

2 motorized axes (manipulator arm tilting and (continous) rotation of the sample stage)

Sample shutter and sample release unit (part of the manipulator head), both pneumatically driven.

Temperatures

Room temperature (not stabilized) up to 1000°C

Special features

Sample tilting enables glace angle deposition

Sample preparation features

Load lock chamber

Oxydation / Nitration

max. 10-2 mbar neutral oxygen / nitrogen gas (using a manual gas dosing valve)